Druckspiegel - News

Antalis präsentiert Pergraphica® Spectrum of Impressions

Mit der Einführung des Pergraphica® Spectrum of Impressions Print Books von Mondi setzt Antalis neue Maßstäbe zur Inspiration durch hochwertige Design-Papiere. Die sorgfältig kuratierte Kollektion ungestrichener Feinstpapiere wurde entwickelt, um Printdesigns durch die perfekte Verbindung von Weißtönen und Haptik auf ein neues Niveau zu heben.

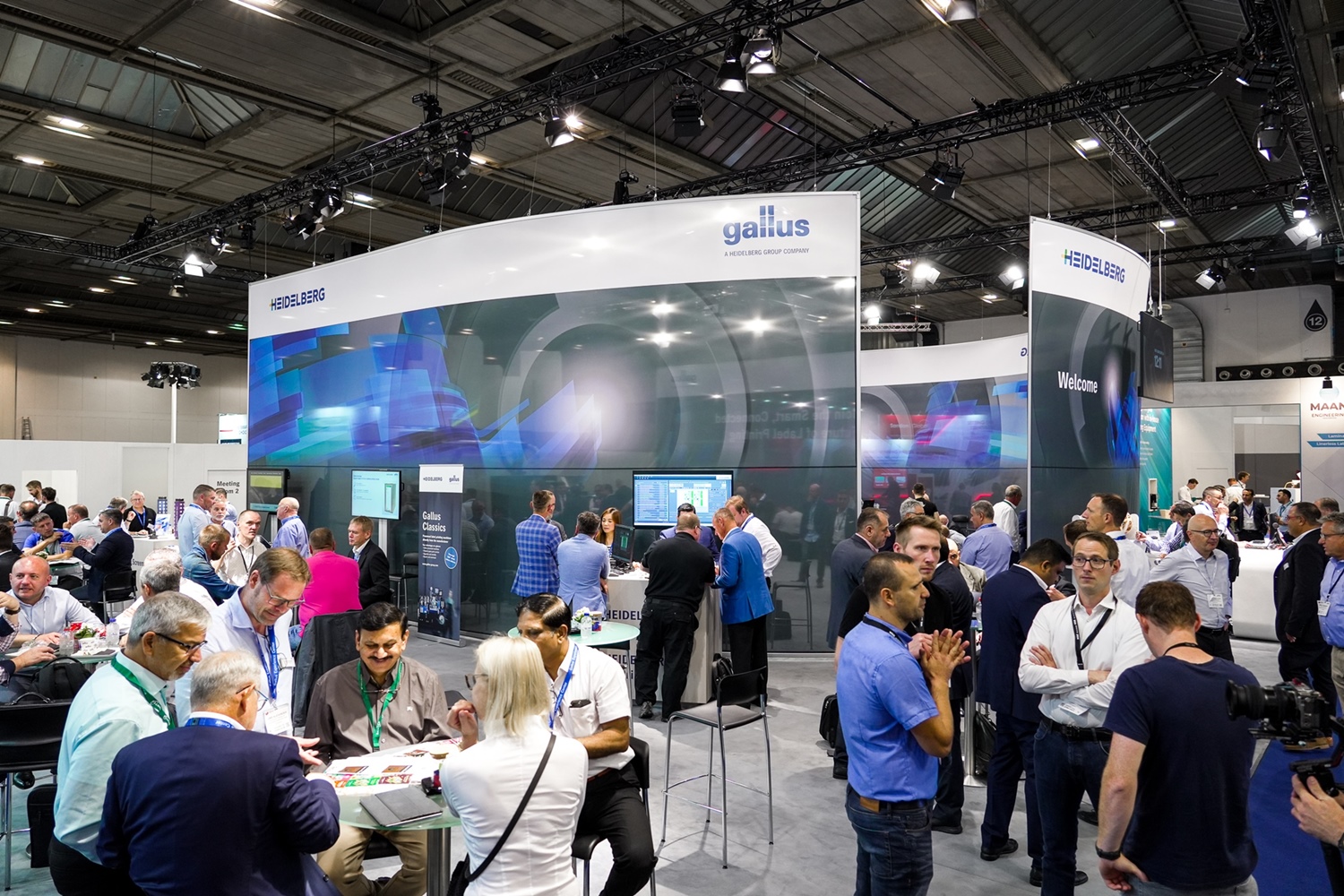

Labelexpo

Heidelberg und Gallus: Neue Lösungen für den wachsenden Etikettenmarkt

Die Heidelberger Druckmaschinen AG (Heidelberg) und Gallus werden auf der Labelexpo Europe 2025 (Stand 3E23-3E29) zwei neue Maschinenlösungen für die intelligente und vernetzte Etikettendruckproduktion vorstellen. Der Bedarf an kleineren Auflagen und kürzeren Durchlaufzeiten in der Etikettenbranche nimmt ständig zu und stellt Produzenten vor die Herausforderung, trotz einer komplexen Marktdynamik und sinkenden Margen ein hohes Maß an Produktivität und Rentabilität zu erreichen.

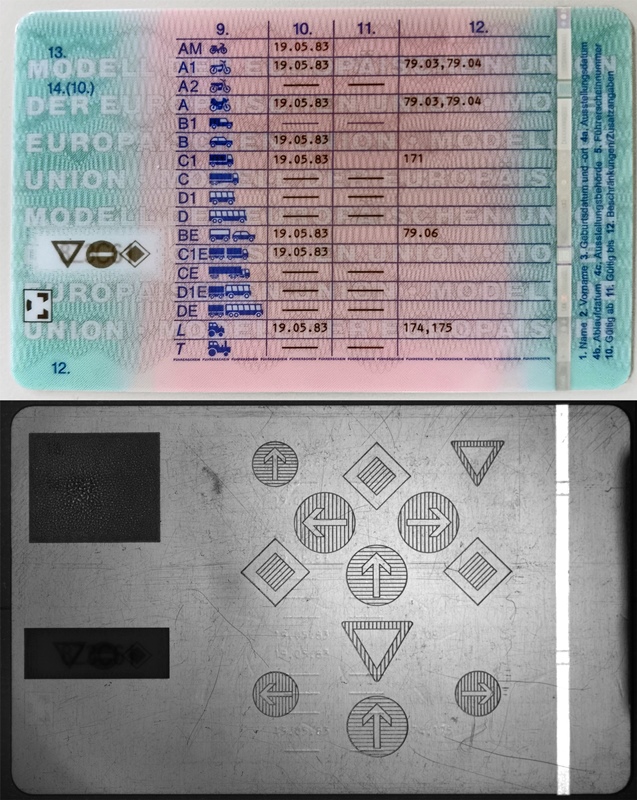

Feinste Prägungen klar sichtbar gemacht

Der Bildverarbeitungsexperte Bi-Ber hat ein Kamerasystem zur Visualisierung von Prägungen auf reflektierenden Oberflächen entwickelt. Verschiedenartige Prägungen müssen sichtbar gemacht werden: Hoch- und Tiefprägung mit minimal 10 µm Höhenunterschied zum Trägermaterial und unterschiedlich große und feine Strukturen mit minimalen Strichbreiten von ca. 40 µm. Die Visualisierung dient zur Prüfung auf Anwesenheit und Vollständigkeit von geprägten Schriftzügen und Grafikelementen. Bi-Ber erhielt den Auftrag, nachdem Versuche mit einem 2D/3D-Laser-Wegmesssystem gescheitert waren. Die 3D-Technologie konnte die extrem flachen Prägungen nicht erfassen, und die 2D-Technologie hatte eine zu geringe laterale Auflösung. Bi-Ber entwickelte eine kosteneffiziente Lösung auf Basis von Standardkomponenten.

Neue Ricoh Pro™ C5400-Serie überzeugt durch höhere Geschwindigkeit

Ricoh hat die Markteinführung der neuen Pro C5400-Serie für den Farbproduktionsdruck bekanntgegeben. Die neuesten Produktionsdrucksysteme kombinieren eine höhere Produktionsgeschwindigkeit mit verbesserter Benutzerfreundlichkeit. Die Ricoh Pro C5400-Serie wurde entwickelt, um auch weiterhin die vielfältigen Anforderungen von kommerziellen Druckdienstleistern und internen Druckzentren zu erfüllen.

FachPack

Mettler-Toledo präsentiert Lösungen für Produktqualität und -konformität auf der Fachpack

Mettler-Toledo Produktinspektion, ein weltweiter Anbieter von Präzisionsinstrumenten und Inspektionslösungen, nimmt vom 23. bis 25. September als Aussteller an der Fachpack 2025 in Nürnberg teil. Das Unternehmen präsentiert auf der Messe seine neuesten Innovationen für Fremdkörpererkennung, Gewichtskontrolle und Etikettenprüfung, die Herstellern helfen, die Sicherheitsvorschriften für Lebensmittel und Pharmazeutika einzuhalten, die Produktivität zu steigern und kostspielige Verschwendung zu reduzieren.

BVDM informiert gemeinsam mit der Bundesanstalt für Landwirtschaft und Ernährung über EUDR-Umsetzung

Am 13. August 2025 informiert der Bundesverband Druck und Medien e.V. (BVDM) gemeinsam mit der Bundesanstalt für Landwirtschaft und Ernährung (BLE) in einer weiteren Online-Veranstaltung „infoKompakt Entwaldungsfreie Druckprodukte – Update August 2025“ über die Umsetzung der EU-Entwaldungsverordnung (EUDR) in der Druckindustrie.

Labelexpo

VPF auf der Labelexpo in Barcelona

Vom 16. bis 19. September 2025 wird die Labelexpo Europe erstmals in der spanischen Metropole Barcelona ausgerichtet – und die VPF GmbH & Co. KG, Spezialist für innovative Haftmateriallösungen, ist mit einem völlig neuen und großzügig gestalteten Messestand vor Ort dabei.

Jürgen Lemke wird neuer COO Paper bei Klingele

Die Klingele Paper & Packaging Group erweitert ihre Geschäftsleitung: Jürgen Lemke übernimmt ab sofort die Position des Chief Operating Officer (COO) für den Bereich Paper. In dieser Rolle verantwortet er die weltweiten Papieraktivitäten der Gruppe mit den Papierfabriken in Weener (D), Nova Campina (BRA) und Straßburg (F), sowie die Versorgung der Wellpappenwerke der Klingele Gruppe mit Papier. Ein weiterer Schwerpunkt liegt auf der strategischen Weiterentwicklung des Geschäftsbereichs und der Optimierung der Auslastung der Papierfabriken.

Fehlverhalten in KMU bedroht IT-Sicherheit – besonders am Freitag

Ob dubiose E-Mails, ungesicherte WLAN-Verbindungen oder verdächtige Webseiten, eine der goldenen Regeln im Arbeitsalltag lautet: „Auf keinen Fall anklicken.“ Soweit die Theorie – die Realität jedoch zeigt, dass ein zunehmendes Bewusstsein für Cyberbedrohungen noch längst nicht bedeutet, dass Büroangestellte sich auch entsprechend vorsichtig verhalten. So ergab eine von Sharp unter insgesamt 1.001 österreichischen Arbeitnehmern in KMU durchgeführte Umfrage, dass fast zwei Drittel der Befragten (61 Prozent) im Arbeitsalltag riskante Verhaltensweisen in Sachen IT an den Tag legen, die sie vor ihren Vorgesetzen verheimlichen.

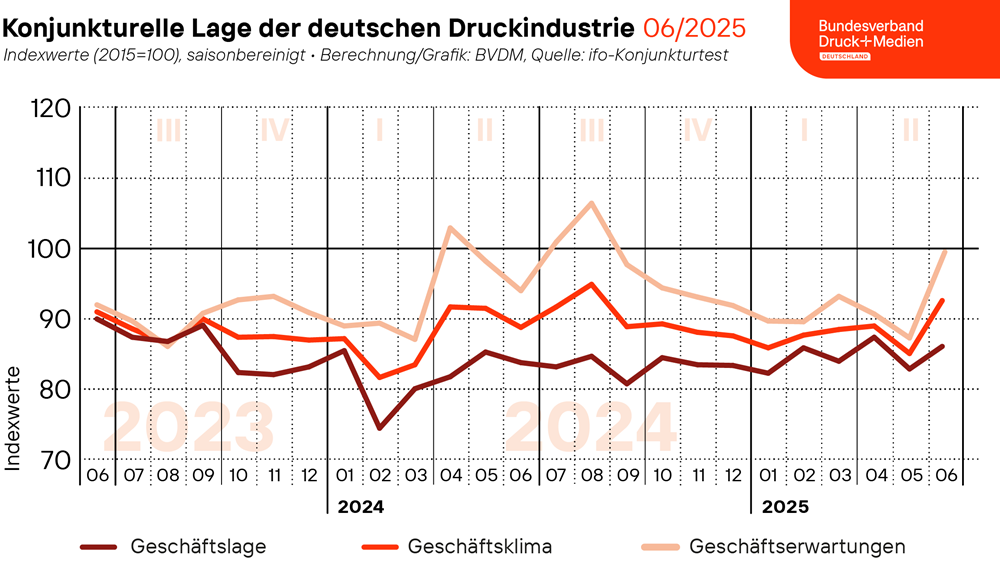

Deutliche Stimmungsaufhellung in der Druck- und Medienbranche im Juni

Im Juni 2025 verbesserte sich das saisonbereinigte Geschäftsklima der deutschen Druck- und Medienindustrie deutlich. Der vom Bundesverband Druck und Medien ermittelte saisonbereinigte Geschäftsklimaindex wies gegenüber dem Vormonat einen Anstieg von 8,7 Prozent auf. Mit 92,8 Punkten lag der Index damit im Juni rund 4,3 Prozent über dem Niveau des Vorjahresmonats. Sowohl die aktuelle Lageeinschätzung als auch die Geschäftsaussichten für die nächsten sechs Monate fielen deutlich optimistischer als im Vormonat aus, wobei der Anstieg des Geschäftsklimaindex hauptsächlich durch die deutlich verbesserten Geschäftserwartungen beeinflusst wurde.

Jahresbilanz Druck- und Medienbranche Österreich: 1,85 Milliarden Euro Umsatz

Das Jahr 2024 war für die Druck- und Medienbranche herausfordernd. Mit einem Jahresumsatz von 1,85 Milliarden Euro schließt die Branche schon das zweite Jahr in Folge mit einem Minus ab. Für 2025 hofft der Verband Druck Medien auf eine Stabilisierung der Wirtschaftslage. Erste Hinweise auf Erholung gibt es bereits, etwa in steigenden Werbeausgaben. Der Verband Druck Medien appelliert, auf Druck aus Österreich zu setzen.

Jungdruck GmbH: Neue Marke proteclabel ins Leben gerufen

Die Jungdruck GmbH, in Radevormwald ansässiger Anbieter von Spezialetikettenlösungen für die Chemie- und Tierfutterindustrie, blickt positiv in die Zukunft. Anlass dafür ist die neue Firmen-Marke proteclabel, unter deren Namen innovative Mehrlagenetiketten entsprechend der sogenannten CLP-Verordnung angeboten werden. Diese besagt, dass trotz fehlenden Platzes auf Behältnissen umfassende Warnhinweise, Sicherheitsangaben und mehrsprachige Informationen veröffentlicht werden müssen. Gernot Jung, Geschäftsführer des Familienunternehmens: „Wir sind einer der wenigen Anbieter in Europa, die den Herstellern passende Lösungen für diese Herausforderung anbieten können.“