Package Printing News

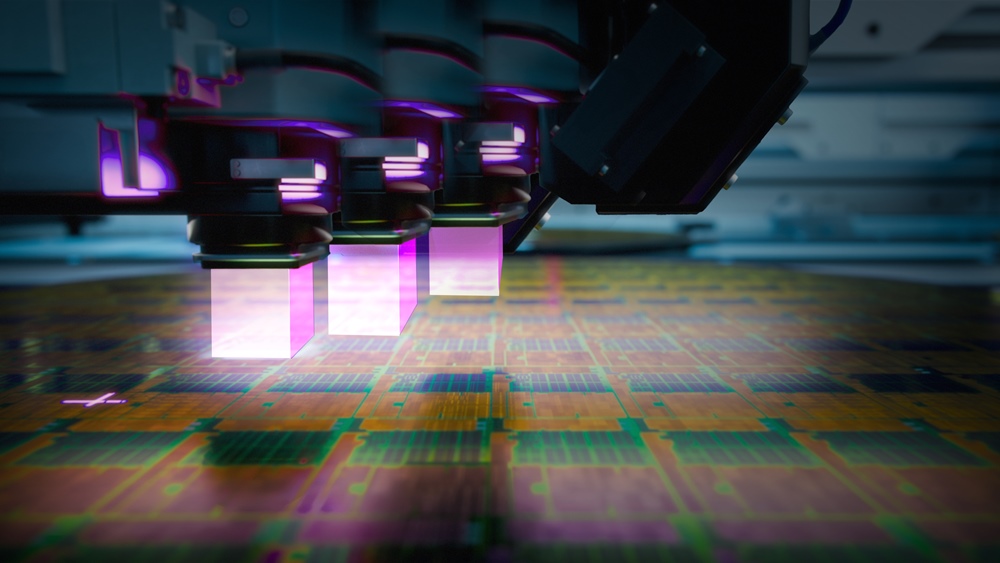

TI DLP® technology delivers high-precision digital lithography for advanced packaging

Texas Instruments is enhancing the next generation of digital lithography with the introduction of the DLP991UUV digital micromirror device (DMD), the company’s highest resolution direct imaging solution to date. With 8.9 million pixels, sub-micron resolution capabilities and a data rate of 110 gigapixels per second, the device eliminates the need for expensive mask technology while delivering the scalability, cost-effectiveness and precision needed for increasingly complex packaging.

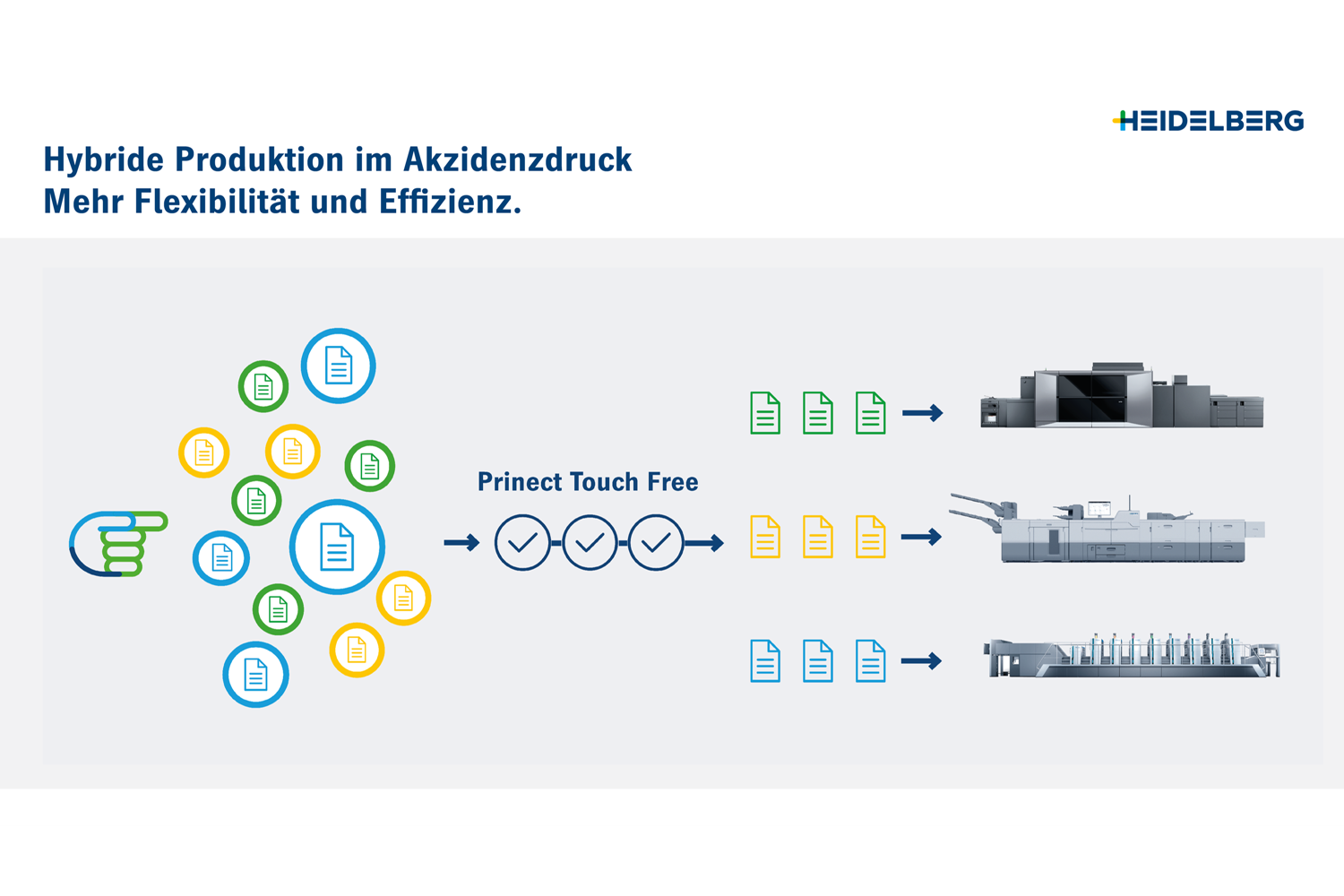

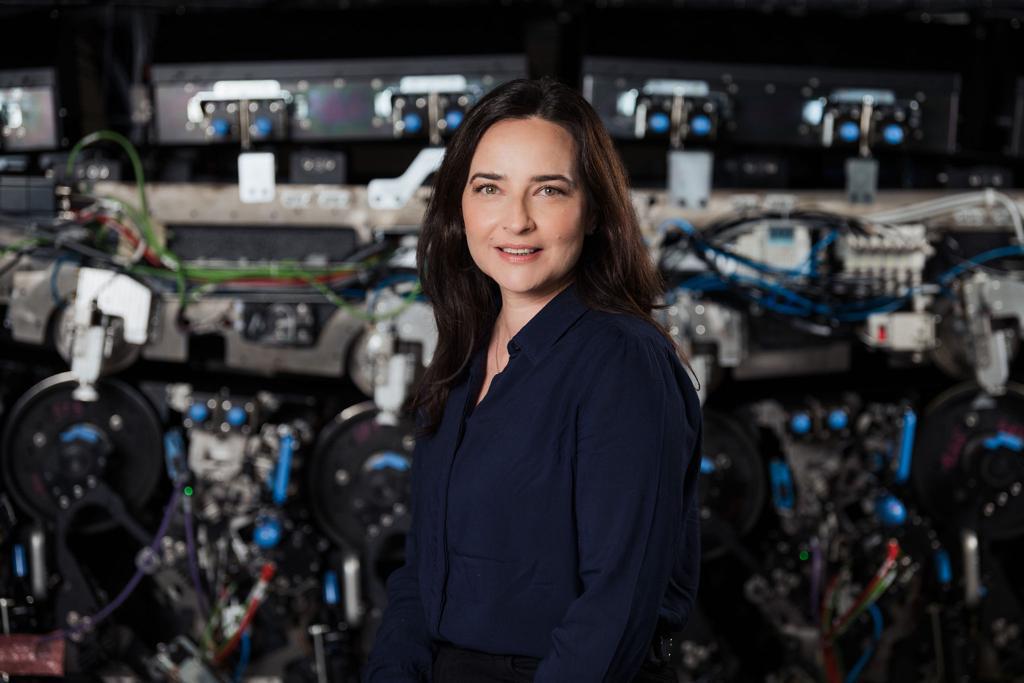

Heidelberg welcomes more than 200 international guests from the printing industry to Shift 2025

Enormous cost and competitive pressure, as well as the increasing difficulty of recruiting suitable personnel on the market, are driving the printing industry. An additional challenge is the fact that printing companies now have to generate a significant portion of their revenue, which they previously achieved with high-volume orders, through a large number of small orders. With conventional working methods, it is difficult to manage such an order structure economically.

UPM Adhesive Materials receives RecyClass recognitions

UPM Adhesive Materials has received recognitions from RecyClass for its releasable general purpose RW85C adhesive. In addition to the previously acquired approvals, label materials with RW85C adhesive are now recognized to be releasable in the HDPE (High Density Polyethylene) container recycling and alkali/water releasable adhesive in the PET bottle recycling1. This means that the approved label materials can be recycled in HDPE natural and white and PET bottle recycling streams, further enhancing recyclability and supporting the circular economy.

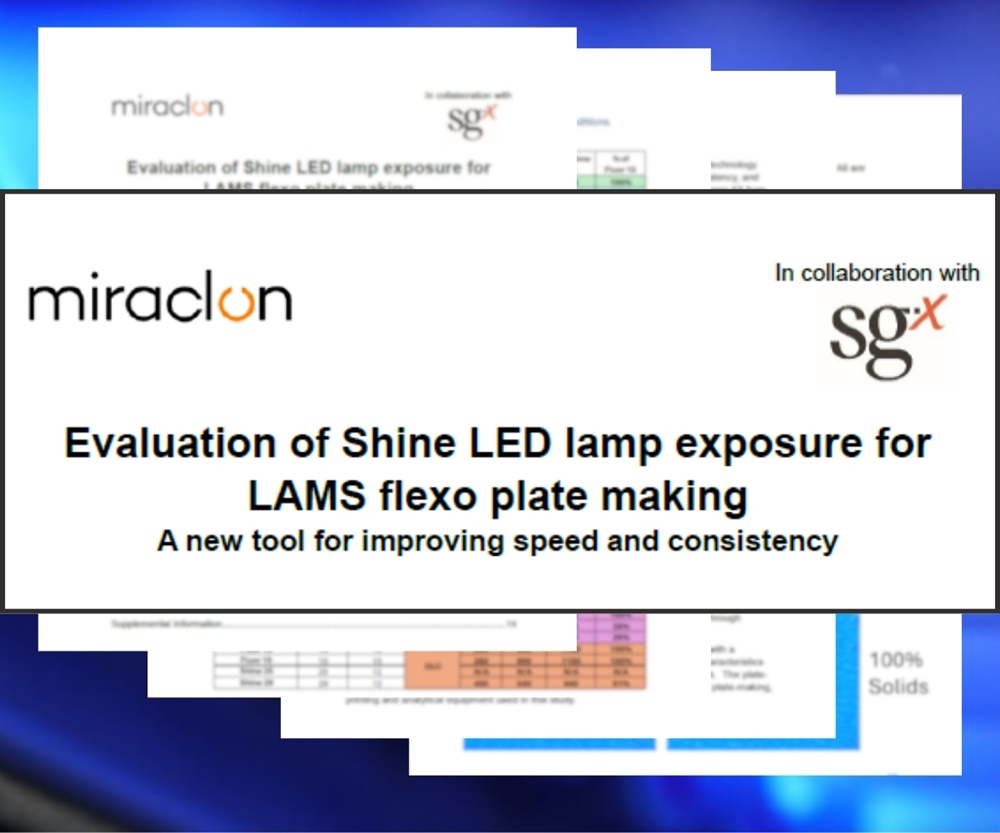

Miraclon and SGX collaboration validates Shine LED Lamp Kit performance on LAMS flexo plates

Miraclon, in partnership with US-based trade shop, SGX, has concluded a recent study that confirms the Shine LED Lamp Kit, innovated by Miraclon, produces high-quality plates that provide measurable benefits for a full range of LAMS flexo plates over fluorescent exposure. The results from the collaboration, which included comprehensive testing of five different LAMS plate types, have been published in a technical paper – available from Miraclon.

Holmen Board and Paper launches next generation lightweight kraftliner

Holmen Elevate is the “lightest kraftliner on the market”, available in 72, 82 and 92 gsm. The kraftliner is well suited for e-commerce, shelf-ready and food packaging applications where both sustainability and performance are essential.

Labelexpo

New water-based ACTDigi® LEP Primer

Actega, manufacturer of specialty coatings, inks, adhesives, sealants and compounds for the print and packaging industry, has launched its water-based ACTDigi® LEP Primer at Labelexpo Europe 2025 (16-19 September, Fira Gran Via, Barcelona, Spain, Actega booth 3D41). Developed in partnership with HP and included in HP’s newly expanded in-line primer portfolio, the ACTDigi® LEP Primer ensures optimal print performance for different types of labels produced on a wide range of substrates, including coated and uncoated paper, synthetics and metalized substrates. This exceptional performance is proven on even the most challenging structured substrates, such as velvety papers and wine labels.

Labelexpo

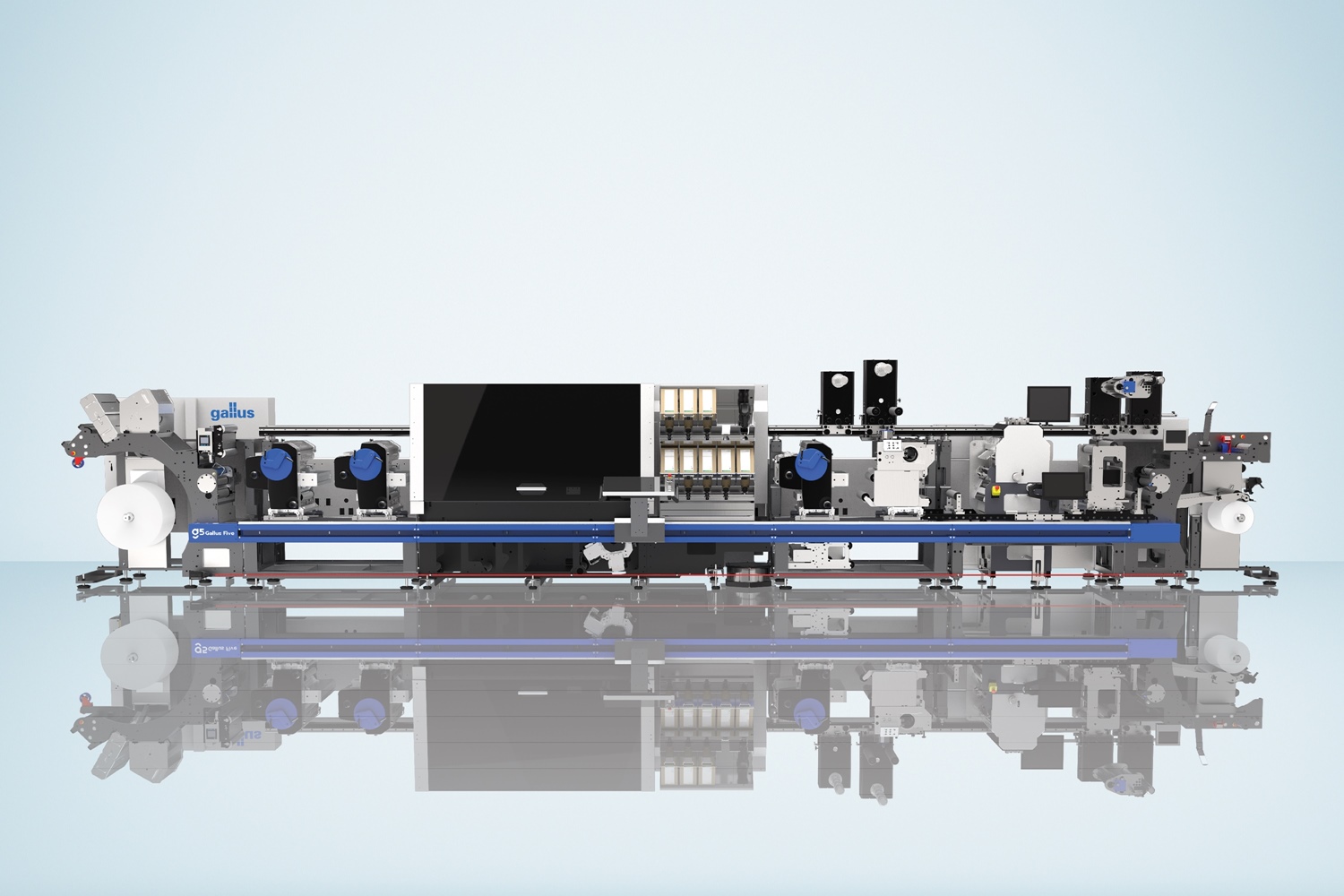

Gallus and Heidelberg unveil new digital and hybrid solutions to meet rising demand across the label market

Gallus, a subsidiary of Heidelberger Druckmaschinen AG (Heidelberg), today announces the launch of two new presses, one all-digital and one hybrid, at Labelexpo Europe 2025. These additions to its System to Compose portfolio have been strategically developed together by Heidelberg and Gallus to address the pressing and evolving needs of label producers to deliver greater speed, flexibility, and high-quality output.

Labelexpo

UPM Adhesive Materials showcases its solutions for label material performance at Labelexpo Europe 2025

UPM Adhesive Materials, formerly known as UPM Raflatac, has announced the launch of a range of specialist solutions that address key trends in Logistics and Durables. These, together with other innovations, will be presented on its stand (3D29) at the forthcoming Labelexpo Europe show, taking place in Barcelona from 16th to 19th September. This event marks UPM Adhesive Materials’ debut under its renewed brand identity, reflecting its commitment to adhesive material expertise, sustainability and helping customers renew the everyday with label material performance.

FachPack

New process for the economical production of barrier-coated flexible paper packaging solutions

With regard to a functioning circular economy, flexible paper packaging as a substitute for plastics, also known as "paperization," is becoming increasingly important. Flexible paper packaging is predicted to grow by 4.5 percent annually until the end of the decade. An expert survey conducted by the Baden-Württemberg Cooperative State University Heilbronn (DHBW) and Heidelberger Druckmaschinen AG (Heidelberg) confirms this trend.

Mondi’s paper-based CompressWrap sets new standards for Ekornes’ mattresses

Mondi is partnering with Ekornes, one of the Nordic region’s largest furniture producer, to introduce an innovative paper-based packaging solution for wrapping high-end mattresses, replacing the previous plastic solution.

Walki adds printing capacity to meet growing demand for future-proof flexible packaging

Walki Westpak has made sizable investments to meet the rising demand for recyclable flexible packaging. The company is expanding its production capacity by acquiring a new printing press and constructing a new post-processing hall.

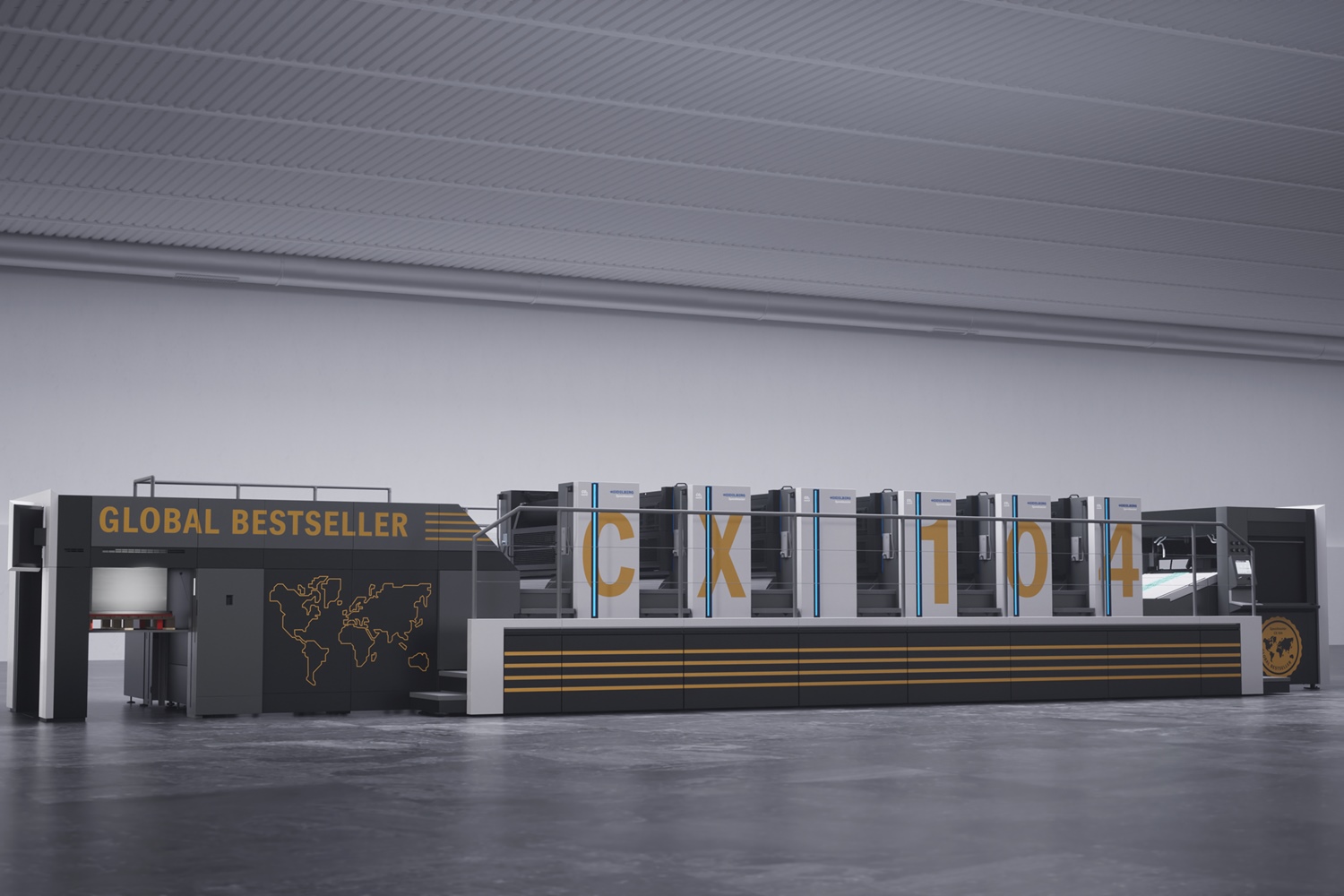

One for everyone and everything! The bestseller from Heidelberg: Speedmaster CX 104

The Speedmaster CX 104 was first unveiled at China Print 2021 and has since been installed over 950 times. More than 6,100 of its printing, coating, and drying units have been delivered worldwide, making it the biggest-selling sheetfed offset printing press that Heidelberger Druckmaschinen AG (Heidelberg) has ever made, relative to its start of production. In one year, all the systems installed globally churned out a collective total of eleven billion printed sheets.