Package Printing News

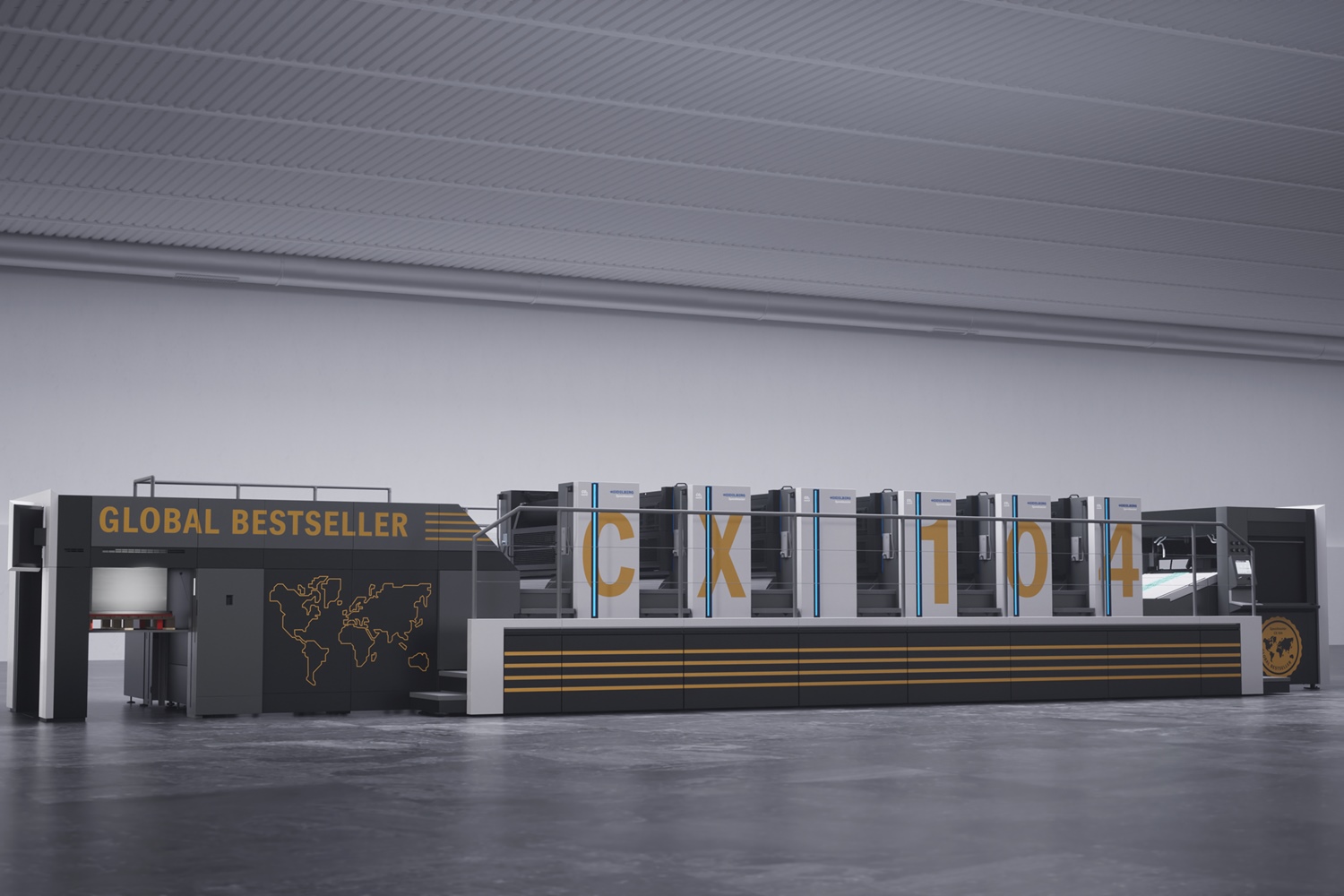

One for everyone and everything! The bestseller from Heidelberg: Speedmaster CX 104

The Speedmaster CX 104 was first unveiled at China Print 2021 and has since been installed over 950 times. More than 6,100 of its printing, coating, and drying units have been delivered worldwide, making it the biggest-selling sheetfed offset printing press that Heidelberger Druckmaschinen AG (Heidelberg) has ever made, relative to its start of production. In one year, all the systems installed globally churned out a collective total of eleven billion printed sheets.

Labelexpo

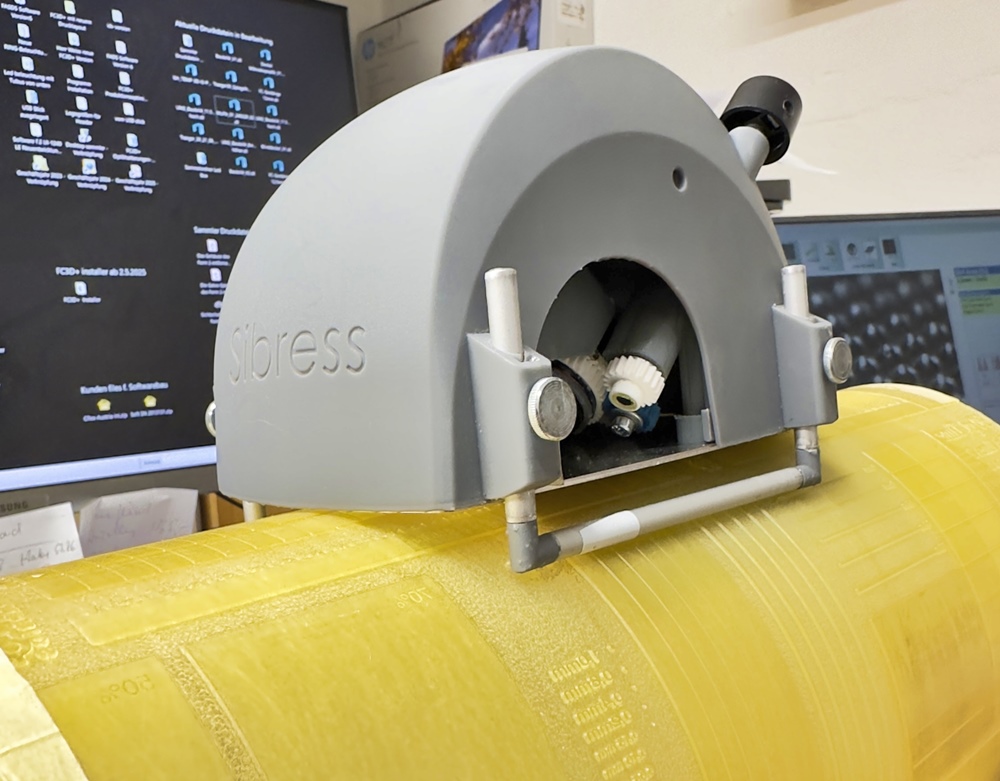

Sibress to showcase new version of FlexoControl 3D Plus for photopolymer sleeves

Sibress, a manufacturer of measuring and analysis systems for the quality control of flexographic and packaging printing, will be presenting its entire current product portfolio at Labelexpo Europe 2025 in Barcelona. As a new innovation, the company will unveil a version of the FlexoControl 3D Plus device for measuring photopolymer sleeves.

K

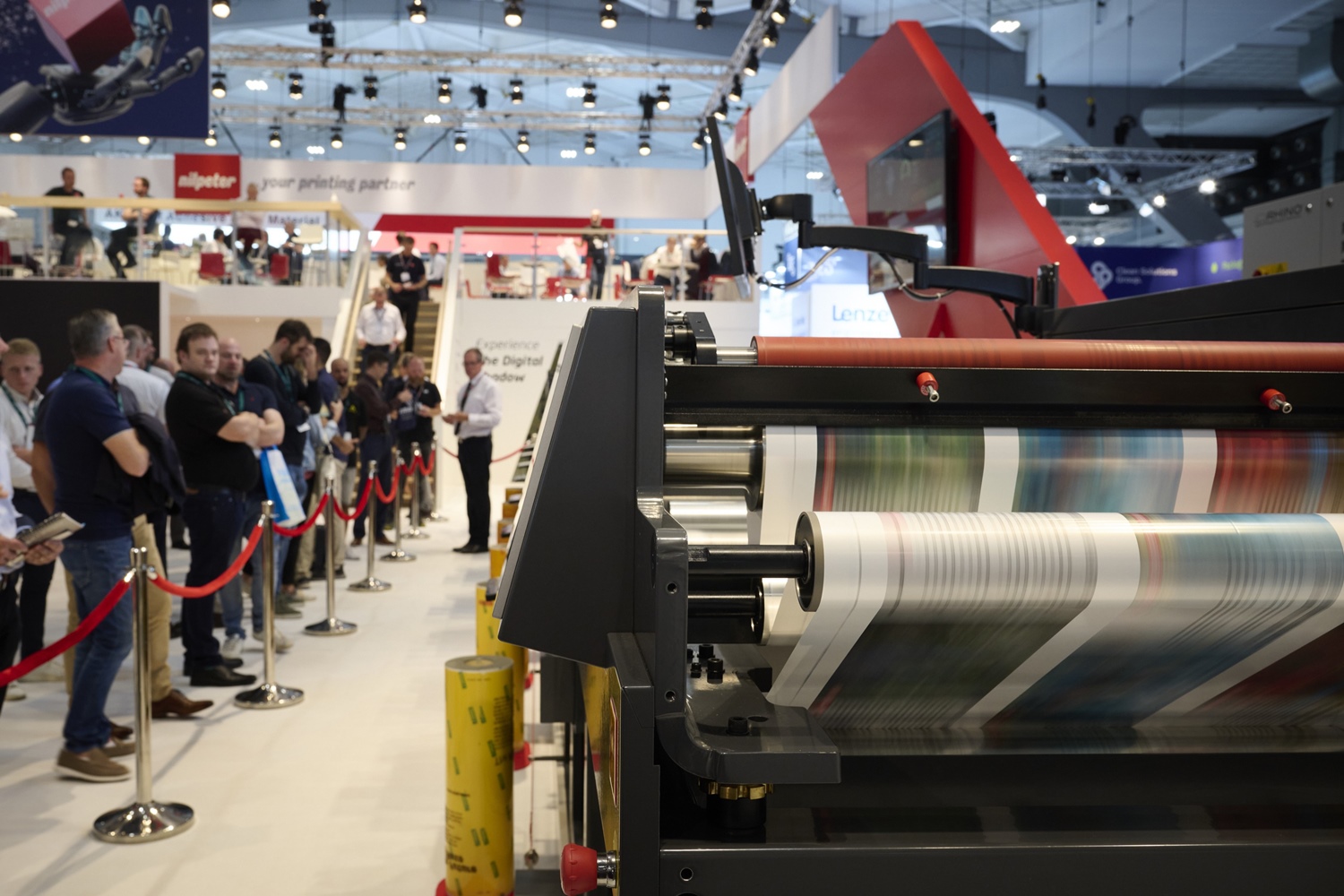

Windmöller & Hölscher to Present Varex II and Alphaflex at K 2025

German machine manufacturer and flexible packaging specialist Windmöller & Hölscher (W&H) will exhibit at K 2025 in Düsseldorf, Germany, from October 8–15, as well as at its In-house Expo at company headquarters in Lengerich. Highlights include a new development for MDO lines, solutions for easier machine operation, and a range of sustainable packaging applications. A special highlight: W&H will feature two running machines at its booth, with live demonstrations in extrusion and printing.

FachPack

Atlantic Zeiser presents CodeVault and 2D Code Readiness at Labelexpo 2025

Atlantic Zeiser, a Coesia company and global player in digital packaging printing and card personalization solutions, will present its latest software and printing innovations at Labelexpo Europe 2025, taking place from September 16 to 19 at Fira Gran Via in Barcelona (Booth L95). Atlantic Zeiser will highlight solutions that enable brand owners and print-houses to meet evolving global serialization requirements, strengthen supply chain security, and leverage packaging codes for operational and marketing benefits.

BW Packaging announces 2025 lineup for Pack Expo Las Vegas

BW Packaging, Barry-Wehmiller’s packaging machinery group, has announced its packaging machinery lineup for Pack Expo, which will be held in Las Vegas Sept. 29–Oct. 1. This year, BW Packaging will feature many of its popular solutions and beloved machinery brands, including Thiele for bag filling, Hayssen for flow wrapping and vertical form-fill-seal bagging, Angelus for seaming and Pneumatic Scale|Angelus for craft beverage canning lines at Pack Expo Las Vegas booth W-3100.

Labelexpo

Where performance grows: MPS unveils EF Packaging and Performance Ecosystem

At this year’s Labelexpo Europe 2025 in Barcelona, MPS will debut two powerful solutions designed to help converters achieve higher efficiency, better quality, and stronger business results: EF Packaging and the Performance Ecosystem. The show runs from 16–19 September 2025 at the Fira Gran Via, marking the first time Labelexpo Europe will take place in Spain.

Toyo Ink Europe Steraflex GIO UV: A new standard in low migration UV flexo inks

Toyo Ink Europe N.V., a member of Japan’s artience Group (formerly Toyo Ink Group), has recently added the Steraflex® GIO UV to its existing portfolio of flexographic printing inks. The new ink system offers superb print and press performance on most label substrates, sleeves and other applications where migration is a key priority. Moreover, Steraflex GIO is fully compliant with EuPIA, Swiss Ordinance, the latest ECHA SVHC list and other European regulatory requirements including the German Ink Ordinance, setting a new benchmark in both safety and performance.

Labelexpo

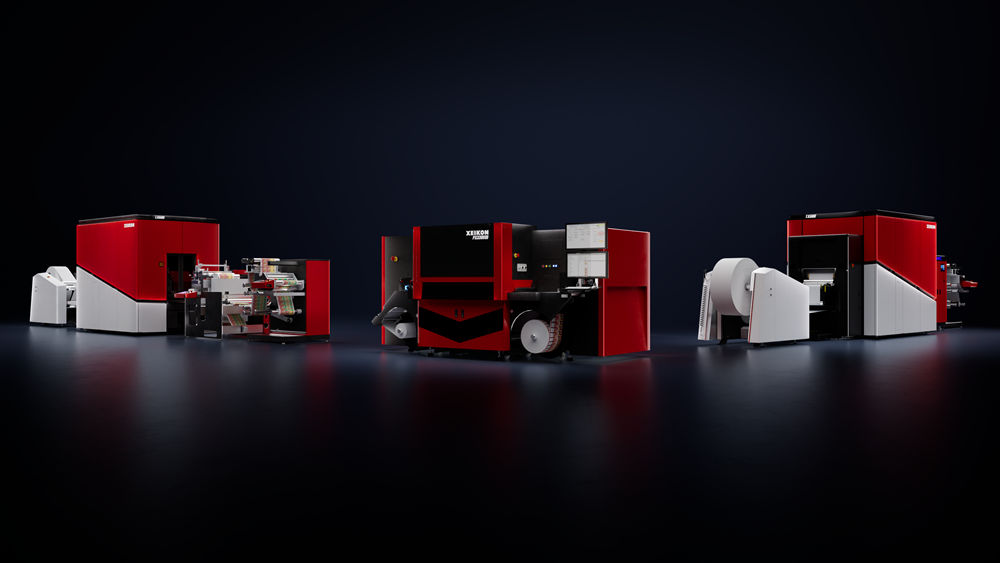

Xeikon brings full-spectrum digital label solutions to Labelexpo Europe

Xeikon is set to make a bold statement at the upcoming Labelexpo Europe. The digital press manufacturer will demonstrate the full power of its label and packaging portfolio through live production, real applications, and smart automation flows.

UPM Adhesive Materials invests in Malaysia factory

UPM Adhesive Materials, formerly known as UPM Raflatac, is investing in a new, state-of-the-art coating line and other facility and material handling upgrades in its label material factory in Johor Bahru, Malaysia. This investment will significantly enhance the factory’s capabilities, quality and efficiency. Additionally, it will increase annual production capacity, enabling UPM Adhesive Materials to better serve its customers and accelerate growth in the Southeast Asian market.

Labelexpo

Label industry's finest to receive global awards at Labelexpo Europe

A stage at the heart of Labelexpo Europe 2025’s community will celebrate label industry’s peers with coveted accolades at Festa Barcelona on the 16th of September. Organized by influential industry publication Labels & Labeling, the inaugural Global Awards will recognize outstanding achievements across three categories: innovation, sustainability - the key focus areas of this year’s show - and Converter of the Year.

PTS Coating Symposium 2025, Bamberg

PTS (Papiertechnische Stiftung) cordially invites to their PTS Coating Symposium 2025 from September 22nd to 24th in Bamberg, the international industry meeting for coating and surface finishing of paper and cardboard materials. The three-day event takes place in the historic city of Bamberg and offers a carefully curated scientific program alongside numerous networking opportunities. Look forward to engaging expert presentations and discussions that will shed light on current developments and future trends in the industry!

Study by DHBW and Heidelberg: The future of packaging is paper

The future of flexible paper-based packaging is bright, with flexible packaging papers predicted to enjoy annual average growth of over 4.5 percent by the end of the decade. This is primarily thanks to their sustainable properties, especially when compared with plastic packaging. An expert survey entitled “The future of packaging 2030”, which was conducted by Baden-Württemberg Cooperative State University (DHBW) Heilbronn in collaboration with Heidelberger Druckmaschinen AG (Heidelberg), has now corroborated this development.