Druckspiegel - News

ECO3 presents Apogee v15

ECO3 announces the release of Apogee v15, the latest update to its prepress workflow software for commercial printers. The new version will be presented at CONNECT 2026, taking place February 10–12, 2026, in Las Vegas. CONNECT 2026 is a user conference and industry event organized by Graphic Communications, a long-standing ECO3 partner and part of CAI, and eProductivity Software (ePS).

Fiery FreeForm Create 2.0 sets new bar for print personalization

Fiery, LLC, the print industry’s developer of digital front ends (DFEs) and workflow software, today announced the launch of Fiery FreeForm™ Create 2.0, the latest version of Fiery’s free variable-data print (VDP) software that makes personalized print easier, faster, and more customizable for all users.

Hubergroup confirms full GIO compliance for packaging products

With the German Printing Ink Ordinance (GIO) set to apply from January 2027, manufacturers of printing inks for food packaging are facing strict regulatory requirements aimed at ensuring consumer safety. Compliance with these regulations demands extensive development work, reformulation and thorough testing across product portfolios. Nonetheless, the international ink specialist hubergroup Print Solutions confirms it already fully complies with the German Printing Ink Ordinance today. All hubergroup products intended for food packaging applications meet the requirements defined by the GIO.

Increased availability of Scandia 2000 in the Nordics

Lessebo Paper is entering into a collaboration with Kalmar Kuvert that enables customers in Sweden, Norway and Denmark to order the uncoated premium paper Scandia 2000 in smaller volumes. From 15 January 2026, the paper will be available via Kalmar Kuvert in pack orders and quantities up to a full pallet, complementing Lessebo Paper’s direct sales of larger volumes and project-based orders.

New magazine paper redefines printing

Holmen Aspect is an exceptionally white, wood-containing paper designed to set new standards in magazine printing. Developed for the demands of a transforming market, it ensures sharp visual reproduction and an appealing page thickness even with a low gsm weight.

Chemspec Europe to return to Cologne in May 2026

Chemspec Europe, cross-sector sourcing hub for fine and speciality chemicals, has announced its return to Cologne on 6-7 May 2026. Six months ahead of opening, three quarters of exhibition space has already been sold, with several industry heavyweights already confirmed. The quality line-up includes industry leaders like Evonik, WeylChem, CABB, Saltigo, Seqens, Johnson Matthey, Yashashvi Rasayan, and Brenntag.

New Diamant MC 30: The ideal gateway to hardcover production

With the new Diamant MC 30 book line, Müller Martini is launching a powerful tailored solution for companies looking to enter into industrial hardcover production. This configuration already features essential options, delivering excellent value for money.

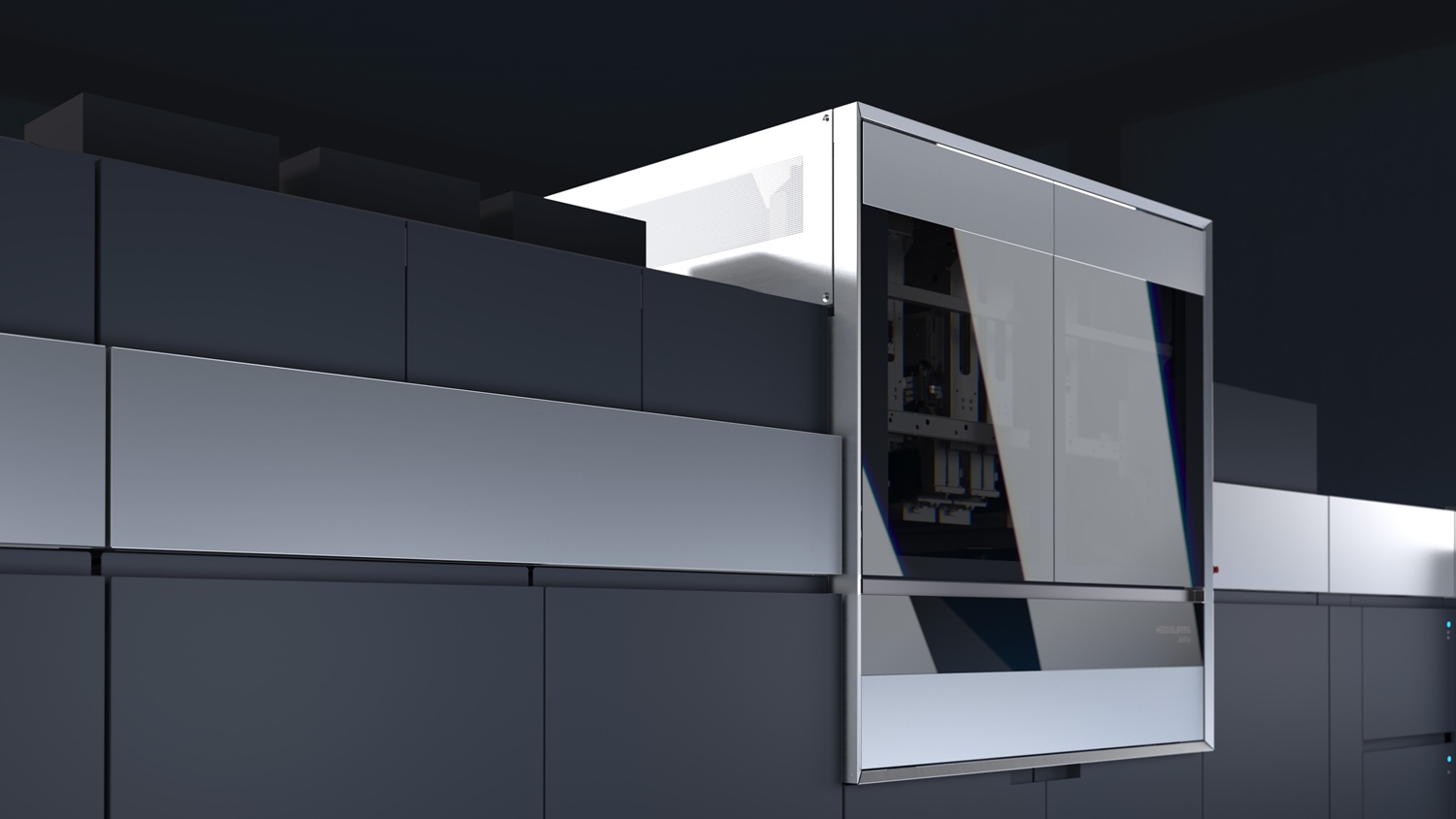

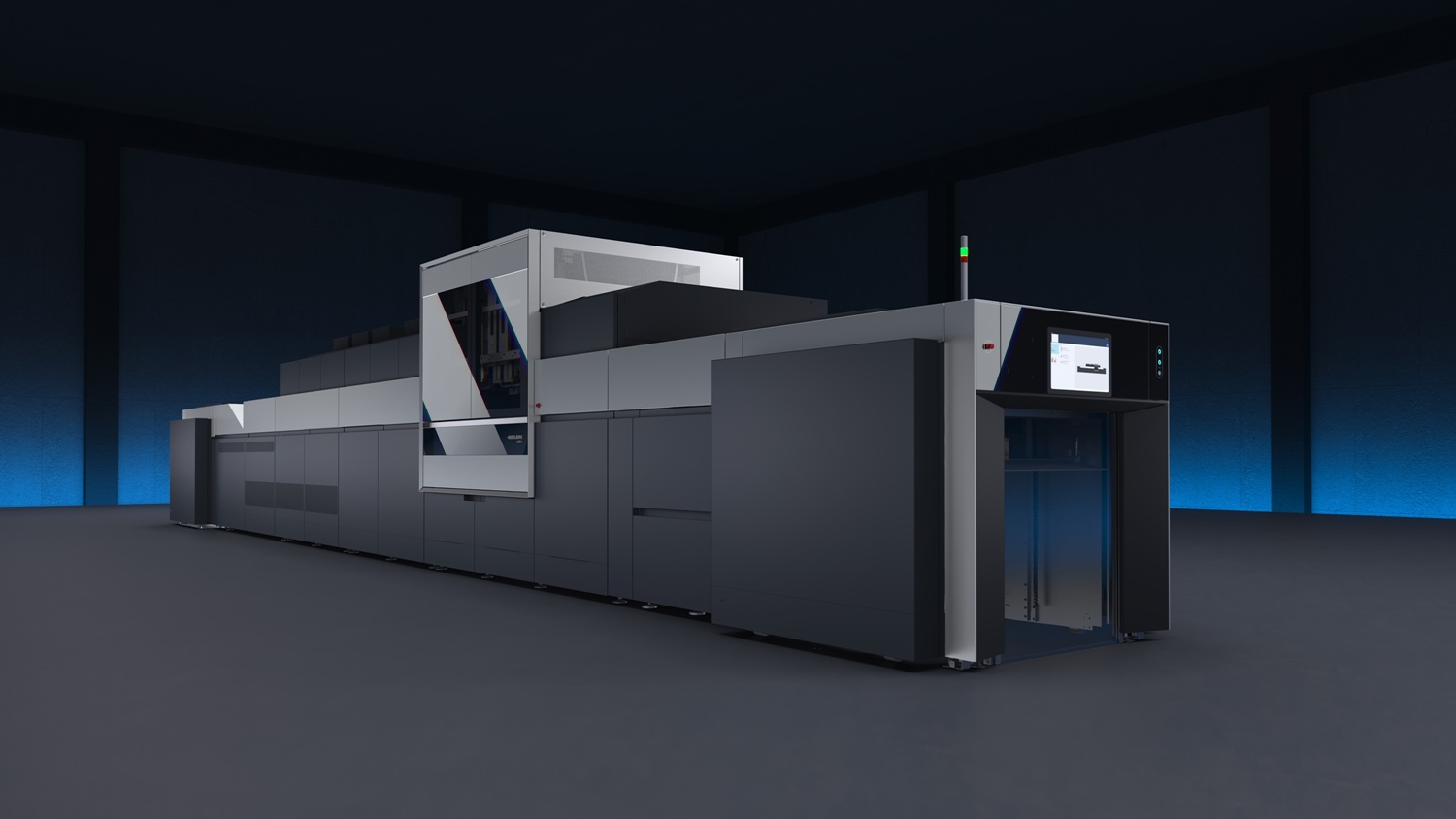

Heidelberg expands digital printing portfolio - Jetfire 75 in B2 format now available

Global volumes in commercial printing are continuing to develop steadily. While the average print run is becoming ever shorter, the number of print jobs is increasing. If print shops are to ensure this order structure is profitable for them, they need more flexibility and automation in their production operations, as well as digitalized processes. Many commercial print shops are therefore increasingly turning to industrial digital printing solutions while also continuing to use highly efficient sheetfed offset printing presses for longer runs. According to forecasts, the global volume of commercial jobs being printed with inkjet technology will grow by over four percent annually up to 2030.

Lessebo Paper launches Lessebo Covers for book covers where precision meets character

Lessebo Paper introduces Lessebo Covers, a premium uncoated paper developed specifically for book covers where material choice plays a decisive role in both expression and performance. Created to balance technical precision with tactile character, Lessebo Covers is designed to support book designs that need to feel as considered as they look.

Hubergroup Chemicals presents expanded portfolio at Paint India 2026

Hubergroup Chemicals, one of the largest manufacturers in the speciality chemicals sector, will once again showcase its portfolio at Paint India, which takes place from February 19 to 21, 2026, in Mumbai. The chemicals specialist will use this opportunity to present its state-of-the-art portfolio of Resins, Energy Curing UV-Oligomers & UV-Monomers, Additives and Colourants. Moreover, the team will inform about the possibilities of Custom Manufacturing (CMO) of raw materials for the chemical industry at stand no. M9 in Hall 4.

Agfa receives final expert ruling on receivable related to sale of Offset Solutions division to Aurelius

Agfa has received the final report of the independent expert regarding the outstanding receivable under the share purchase agreement that was signed with Aurelius Group for the sale of Agfa’s Offset Solutions division.

Fiery XF 9 unlocks new ways to produce high-value large format print

Fiery, LLC announces the launch of XF 9, the latest release of Fiery’s high-performance software RIP, color management, and workflow solution designed to streamline all aspects of large format print production. Winner of the 2025 Pinnacle Award for best large format RIP software, Fiery XF 9 adds cutting-edge capabilities that unlock new levels of value out of your large format print operations.