NEWS

Fast EasySert system allows for efficient insert-in-insert processing

Baumann Druck – the web offset printing plant for job printing at mgo Mediengruppe Oberfranken in Kulmbach – is a successful producer of printed commercial advertising. In order to ensure the requirements of “insert-in-insert” processing are met efficiently, Baumann has now invested in an EasySert system from Ferag. The positive experiences of working with the Swiss manufacturer made the decision to invest an easy one.

In November 2019, mgo Mediengruppe Oberfranken pooled together six companies under the mgo360 name, offering holistic agency and marketing services under a single roof. Baumann Druck is one of these six companies, in addition to digital agency Edelweiss72, advertising agency Hochvier, creo Druck & Medienservice, Druckzentrum Oberfranken and advertising producer P&H.

“The number of marketing and communication channels has increased constantly in recent years. On one hand, we want to offer clarity to customers in this increasingly complex marketing landscape, while also simplifying handling and interaction between these channels on the other,” explains Jörg Schild-Müller, CEO of mgo360.

At the Kulmbach plant, Baumann Druck focuses primarily on printed commercial advertising. Around 150 employees working in order management, prepress, printing, finishing, in-house transportation and the service workshop ensure smooth production on four heatset printing presses. The main production units are three Manroland Lithoman presses for formats of up to 80 pages, and one Manroland Octoman for eight pages. The majority of the products leave the printing presses as finished products. A smaller portion is sent to cutting machines, folding machines and gatherer-stitchers for finishing into the final product.

A new addition to the finishing portfolio

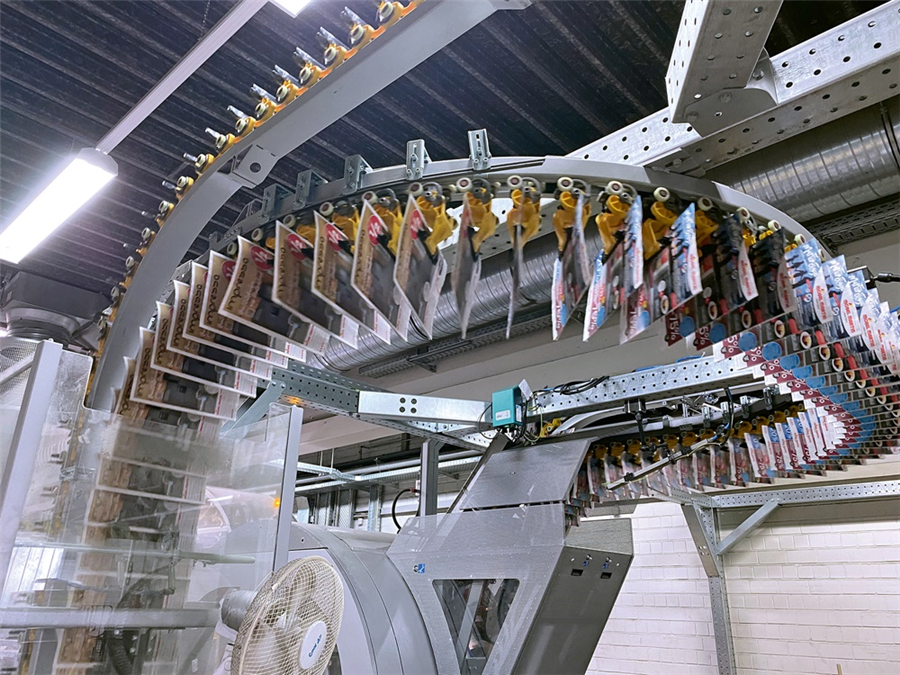

The impetus for the latest investment made in finishing came from “insert-in-insert” processing as required by the customer. In order to insert larger volumes within a short space of time, Baumann Druck ordered a complete Ferag system consisting of an EasySert inserting drum, a FlyStream precollecting line and two JetFeeder insert feeders.

mgo Mediengruppe Oberfranken already had very positive experiences of working with Ferag in the past. Jörg Schild-Müller: “Five years ago, Ferag played a big part in the success of an investment project at our newspaper printing plant at Druckzentrum Oberfranken by reliably keeping to the agreed budgets, schedule and operational performance requirements. This laid the groundwork for successful cooperation with Baumann Druck.”

The contract for the EasySert line was signed in mid-March, with the start of production planned for mid-July 2020. The potential operational performance of various insertion options was analyzed by Ferag prior to conclusion of the contract and included in the agreement as performance guarantees.

Insert-in-insert processing is nothing new for the Kulmbach-based company. However, prior to the commissioning of the EasySert line, this insertion was either bought in from third parties or carried out in-house using another, more technically complex process.

An evaluation of economic feasibility carried out in 2019 clearly favoured a fast, highly specialized insertion system such as the combination of EasySert and FlyStream, which is designed for 30,000 cycles per hour. The system is manually loaded in Kulmbach and the bundles are also removed and stacked by hand. Thanks to the two JetFeeders and the main product hopper on the inserting drum, two different inserts can now be inserted into another “carrier” insert.