NEWS

Seaway turns to latest Heidelberg technology

Operations at Seaway Printing in the USA, a long-standing customer of Heidelberger Druckmaschinen AG (Heidelberg), are geared toward maximum productivity. Above all else, Seaway combines technology and process automation to continuously elevate what’s possible in print. The book and magazine printer recently relocated to a new production facility in De Pere, in the US state of Wisconsin, thereby doubling its production capacity to handle the growth in its business.

Seaway has also become an automation trailblazer in the sector. Its latest investments in Heidelberg prepress, press, and postpress technology have significantly reduced manual interventions and improved efficiency, enabling each of the print shop’s machines to be operated by just one person.

First Plate to Unit press from Heidelberg in the USA

Seaway currently has three Speedmaster XL 106 presses from Heidelberg, including a Speedmaster XL 106-8P that was installed in 2024 and features the Plate to Unit fully automatic plate logistics system – the first such system from Heidelberg in the USA. Besides reducing the workload of operators, this technology also makes plate changes more reliable, minimizes the risk of scratched plates, and helps reduce paper waste.

Seaway’s plate preparation process is further optimized by two new Suprasetter 106 CtP systems with automatic inline plate bending and punching. Thanks to the combined efficiency of Prinect and Suprasetter technology, the team at Seaway can carry out plate production fully automatically and even reallocate one person per shift from the plateroom to more value-adding roles in production.

Higher level of automation and performance

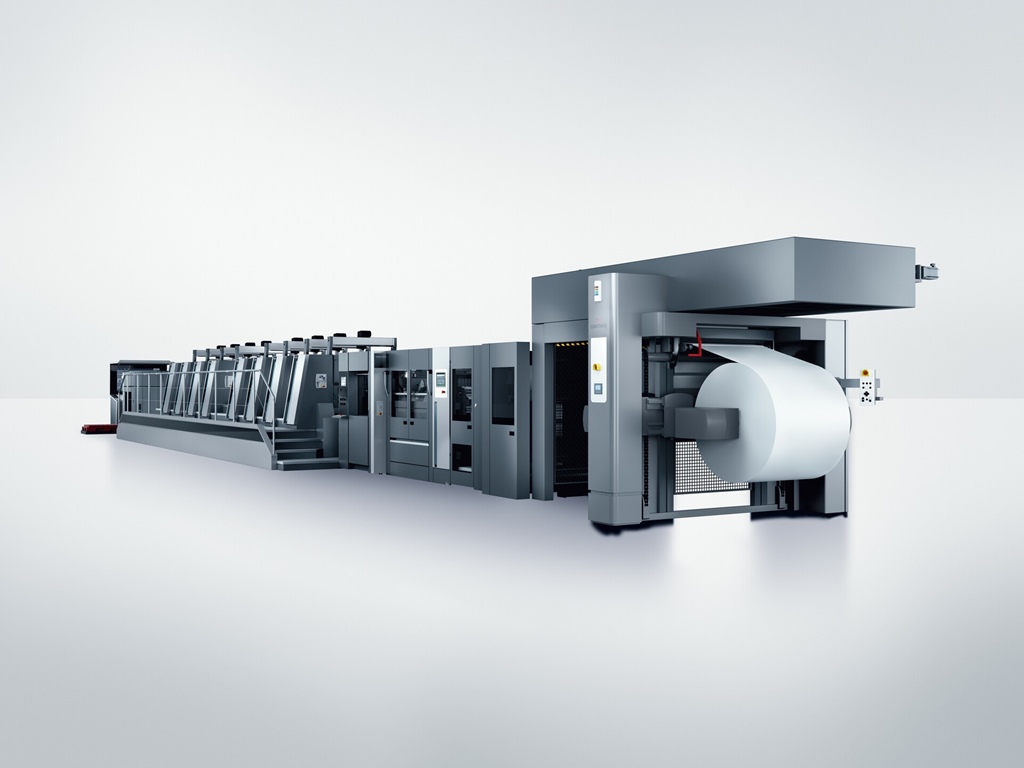

Seaway’s Speedmaster XL 106 from the Peak Performance generation unveiled last year is equipped with additional efficiency-boosting peripherals. These include a non-stop pile-changing system in the delivery for the uninterrupted production of long runs, even at high speeds, Prinect Inpress Control 3 for automatic inline color control, and the CutStar generation 4 inline sheeter. Using reel stock instead of individual sheets means operators are spared the task of reloading the feeder, which results in a two-and-a-half-fold increase in press availability. In addition the company connected its CutStar generation 4 system with the new Contiweb splicer -the first installation of its kind worldwide, which eliminates changeover time between rolls, and saves the company 35-50 minutes every eight-hour shift.

The Peak Performance generation’s highly automated press configuration means only one operator per shift is needed, without this having a negative impact on quality or running speed. As a result, Seaway has seen a 20 percent increase in productivity compared with the eight-color perfecting press it installed in 2018 and has achieved an overall equipment effectiveness (OEE) of 70 percent, which is well above the industry average.

“We configured this press so an operator never needs to be in a particular place at a particular time to maintain productivity. The automation creates a buffer, enabling operators to manage the overall production process while the machine handles individual tasks, such as moving the pile at the delivery or changing a reel, without constant operator intervention,” said Seaway President Kevin Heslin.

End-to-end efficiency

The largely autonomous production process at Seaway continues in the postpress section, where three Push to Stop Stahlfolder TH-P folding machines from Heidelberg move from one folded signature to the next without any operator input. These machines are complemented by three StackStar P robotic stacking systems that autonomously transfer the piles of signature from the delivery onto a pallet.

“Installing the StackStar P made us realize how much time operators spend loading materials from the folder onto pallets. It had an even bigger impact on our finishing operations than we anticipated,” explained Ian Heslin from the Manufacturing Support team at Seaway Printing. The combination of these two technologies makes it possible for Seaway, which folds over 100,000 signatures per shift and folding machine, to have just two operators running all its folding machines and stacking systems.

Innovation is key to being more competitive

Seaway’s sharp focus on investing in the latest technology has helped the company achieve consistent growth of 15 to 20 percent every year for the past decade.

“Ongoing investment in automated technology is essential for staying competitive in the market and achieving our growth and profitability goals. Without it, reaching our productivity targets – particularly for the short-run work that has become our specialty – wouldn’t be possible,” emphasized Kevin Heslin.

Besides helping the company overcome the labor shortage in the market, this focus on automation has also attracted younger workers with a keen interest in technology. “It’s easier to recruit younger staff, because when people come here and see the new equipment, they’d rather work for us than at other production companies in the area,” revealed Ian Heslin.

Looking ahead, Seaway is continuing its search for new ways of making production more efficient and is therefore working closely with the Heidelberg research and development team.

Seaway’s state-of-the-art production line is helping it cut manufacturing costs and achieve job turnaround times that would prove challenging for its competitors. The Heslins sum it up as follows: “Heidelberg machines are unmatched in day-to-day production and the company is always very willing to listen to our recommendations for improvements. It is helping us get the most out of our machines.”